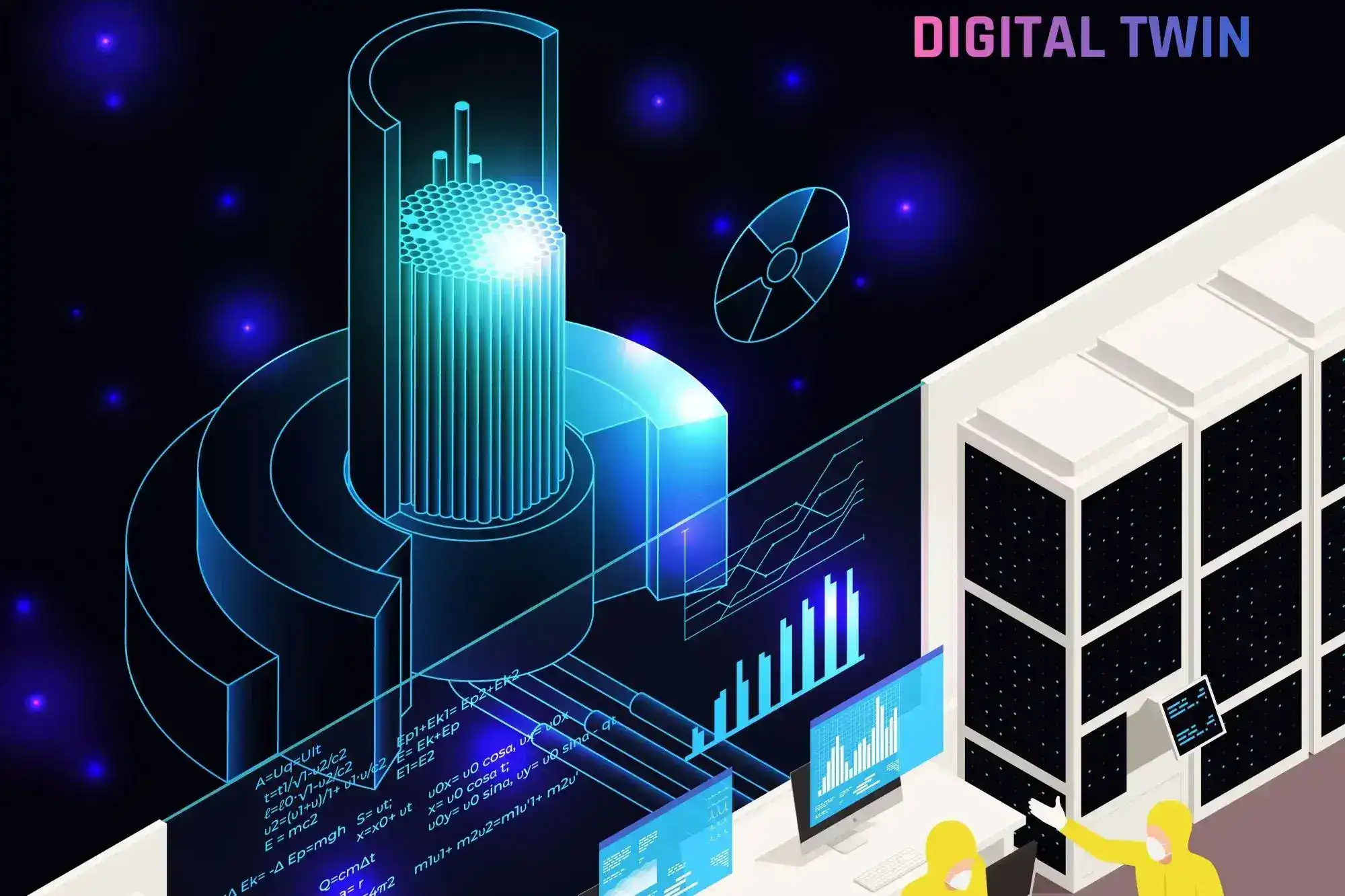

A digital twin is a sophisticated virtual model that replicates a physical object, system, or process. This virtual replica is continuously synchronized with its real-world counterpart through a flow of real-time data. By integrating digital models with real-time data, digital twins provide valuable insights into the state and performance of physical entities. This real-time connection allows for detailed analysis, monitoring, and optimization.

The Evolution of Digital Twins

Early Concepts and Origins

The initial development of digital twins involved basic simulation models used in engineering and manufacturing. These early models were primarily static and lacked real-time capabilities. They served as valuable tools for understanding system behaviors and testing theoretical scenarios. For example, engineers would use these models to simulate stress tests on materials or components before actual implementation.

Technological Advances and Current Trends

Today’s digital twins leverage a range of advanced technologies to enhance their functionality. The following table outlines some of these key technologies:

| Technology | Description | Impact on Digital Twins |

| Internet of Things (IoT) | Devices that collect real-time data from physical entities. | Improves data accuracy and real-time updates. |

| Artificial Intelligence (AI) | Algorithms that analyze data and make predictions. | Enables predictive analytics and autonomous decisions. |

| Big Data Analytics | Techniques for processing and analyzing large volumes of data. | Provides insights and identifies trends for optimization. |

| Augmented Reality (AR) | Technology that overlays digital information on the physical world. | Enhances visualization and interaction with digital twins. |

| Virtual Reality (VR) | Immersive simulations of digital environments. | Provides immersive experiences and detailed modeling. |

| Edge Computing | Processing data closer to the source rather than in a centralized data center. | Reduces latency and improves real-time data processing. |

Applications of Digital Twins

In Manufacturing and Industry

Process Optimization

In the manufacturing sector, digital twins have become indispensable tools for process optimization. By creating virtual models of production lines and processes, manufacturers can:

- Simulate Various Scenarios: Test different process configurations and parameters to identify the most efficient setups.

- Analyze Performance Metrics: Monitor key performance indicators (KPIs) in real-time to ensure optimal operation.

For example, a digital twin of an automotive assembly line can simulate the impact of changing a production parameter, such as the speed of a conveyor belt, on overall output and quality. This allows manufacturers to fine-tune processes without disrupting actual production.

Predictive Maintenance

Predictive maintenance is a significant benefit of digital twins. By continuously monitoring equipment through sensors and updating the digital twin with real-time data, manufacturers can:

- Predict Equipment Failures: Use predictive analytics to forecast when a part is likely to fail and schedule maintenance accordingly.

- Optimize Maintenance Schedules: Plan maintenance activities based on actual equipment conditions rather than predefined schedules.

For instance, a digital twin of a wind turbine can predict when a component might wear out, allowing maintenance teams to replace it before it causes a shutdown. This proactive approach reduces unplanned downtime and extends the life of the equipment.

In Urban Planning and Smart Cities

Infrastructure Management

In urban planning, digital twins are transforming how cities are managed and developed. Virtual models of urban infrastructure help city planners:

- Visualize Infrastructure Components: Create comprehensive models of roads, buildings, and utilities to analyze and optimize their interactions.

- Monitor Urban Dynamics: Track real-time data related to traffic flow, air quality, and energy usage to make informed decisions about urban development.

For example, a digital twin of a city’s transportation system can help planners understand traffic patterns and identify congestion points, leading to better traffic management and infrastructure improvements.

Energy Efficiency

Digital twins also play a crucial role in enhancing energy efficiency within smart cities. By simulating energy consumption patterns and infrastructure performance, cities can:

- Identify Energy Conservation Opportunities: Discover areas where energy use can be reduced and implement strategies to lower consumption.

- Optimize Resource Allocation: Ensure that energy resources are used effectively and reduce waste.

A digital twin of a city’s energy grid can simulate different energy usage scenarios, allowing city officials to test the impact of implementing renewable energy sources or adjusting energy distribution.

In Healthcare

Personalized Medicine

In healthcare, digital twins are revolutionizing personalized medicine by creating patient-specific models and simulating treatment outcomes. For instance, a digital twin of a patient with a chronic condition can be used to test various treatment plans and choose the one that offers the best potential outcome.

Surgical Planning and Simulation

Digital twins also assist in surgical planning and simulation. Surgeons can practice complex procedures using virtual models of patients and enhance precision by anticipating and addressing potential challenges. A digital twin of a patient’s anatomy allows surgeons to plan and practice intricate procedures, reducing the risk of complications and improving patient outcomes.

The Technology Behind Digital Twins

Sensors and Data Collection

Types of Sensors Used

Digital twins rely on various sensors to collect data from physical entities. Some common types include:

- Temperature Sensors: Monitor temperature changes and ensure optimal operating conditions.

- Pressure Gauges: Measure pressure levels in systems such as hydraulic or pneumatic circuits.

- Motion Detectors: Track movement and vibrations in machinery or infrastructure.

These sensors provide real-time data that is crucial for maintaining the accuracy and effectiveness of digital twins.

Data Integration Challenges

Integrating data from multiple sensors into a cohesive digital twin involves several challenges:

- Ensuring Data Consistency: Data from different sources must be consistent and accurately represented in the digital model.

- Managing Data Volumes: Handling and analyzing large volumes of data can be complex and require advanced data processing techniques.

Addressing these challenges is essential for maintaining the reliability and usefulness of digital twins.

Modeling and Simulation Techniques

Real-Time Data Processing

Digital twins rely on real-time data processing to:

- Continuously Update Models: Reflect changes in the physical counterpart and provide up-to-date information.

- Enable Immediate Responses: Quickly address any issues or anomalies detected in the virtual model.

Real-time processing ensures that the digital twin remains an accurate representation of the physical entity, allowing for timely interventions and adjustments.

Advanced Algorithms and AI

Advanced algorithms and AI enhance the capabilities of digital twins by:

- Providing Predictive Analytics: Forecast future conditions and behaviors based on historical and real-time data.

- Enabling Complex Simulations: Model intricate scenarios and interactions to understand potential outcomes and optimize performance.

AI-driven insights and simulations help in making informed decisions and improving the overall effectiveness of digital twins.

Benefits of Digital Twins

Enhanced Decision Making

Digital twins facilitate enhanced decision-making by simulating different scenarios and providing actionable insights. For example, a digital twin of a manufacturing process can simulate the effects of changing a production parameter, helping decision-makers choose the most effective approach.

Risk Management

Digital twins aid in risk management by simulating risk scenarios and developing proactive strategies. Using a digital twin to model potential failures or disruptions allows organizations to develop strategies to mitigate these risks and improve resilience.

Cost Efficiency and Savings

Reduced Downtime

Digital twins contribute to cost efficiency by predicting equipment failures and minimizing disruptions. By using digital twins for predictive maintenance, organizations can avoid costly interruptions and extend the lifespan of their equipment.

Optimized Resource Allocation

Digital twins help in optimizing resource allocation by simulating usage scenarios and reducing waste. For instance, a digital twin of a city’s energy grid can help optimize energy distribution and reduce wasteful consumption.

Challenges and Limitations

Data Privacy and Security

Risks and Mitigation Strategies

The use of digital twins raises several data privacy and security concerns:

- Unauthorized Access: Ensure that sensitive data is protected from unauthorized access and breaches.

- Data Breaches: Implement robust security measures and encryption protocols.

Mitigating these risks involves adopting best practices in data security and regularly updating security measures to address emerging threats.

Compliance with Regulations

Compliance with data protection regulations is essential for:

- Adhering to Legal Requirements: Ensure that digital twin systems comply with relevant data protection laws and regulations.

- Maintaining Trust: Build and maintain trust with stakeholders by demonstrating a commitment to data privacy.

Organizations must stay informed about data protection regulations and implement necessary measures to comply with them.

Integration with Existing Systems

Compatibility Issues

Integrating digital twins with existing systems can present challenges, such as:

- Technology Differences: Address differences between new digital twin technologies and legacy systems.

- Data Format Compatibility: Ensure that data formats are compatible and can be seamlessly integrated.

Overcoming these challenges involves careful planning and implementation strategies to ensure smooth integration.

Implementation Costs

The cost of implementing digital twins includes:

- Technology and Infrastructure Investments: Invest in the necessary hardware, software, and infrastructure.

- Training and Development: Provide training to staff to effectively use and manage digital twin systems.

Organizations should consider these costs when planning digital twin implementations and explore options for cost-effective solutions.

The Future of Digital Twins

Emerging Trends

The integration of digital twins with IoT technologies will enhance data collection by improving real-time data collection and model accuracy, while also expanding applications to enable new use cases across various sectors. As IoT devices become more prevalent, their integration with digital twins will drive innovation and create new opportunities for optimization and efficiency.

Advances in AI and Machine Learning

Advancements in AI and machine learning will enable more advanced simulations, allowing for the modeling of complex scenarios and more accurate predictions of future conditions. AI will also drive autonomous decision-making by using data insights to make decisions without human intervention. The continued evolution of AI and machine learning will further enhance the capabilities and applications of digital twins.

Potential Impact on Various Industries

Evolution in Manufacturing

Digital twins are expected to transform manufacturing processes by improving efficiency, reducing costs, and supporting advanced production techniques. They will also support innovation by facilitating the development and implementation of new manufacturing technologies. The manufacturing industry will benefit from the increased efficiency and innovation driven by digital twins.

Transformation in Urban Development

In urban development, digital twins will help create smarter cities by enhancing planning, resource management, and infrastructure development. They will also improve sustainability efforts by optimizing energy usage and reducing environmental impact. Digital twins will play a crucial role in shaping the future of urban development and creating more sustainable and efficient cities.